Air Compressor Best Safety Pratices: Best Practices for Safe Operation

Published on:

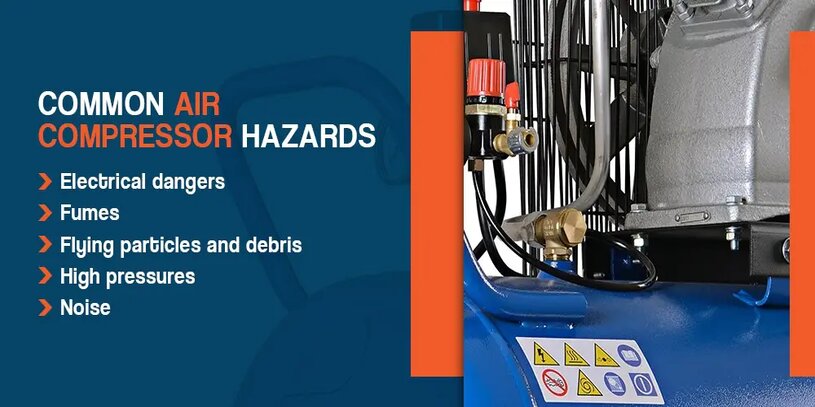

Understanding Air Compressor Safety Risks

While air compressors are valuable tools, they also pose certain safety risks. This blog will outline best practices for operating air compressors safely, minimizing the potential for accidents and injuries. Understanding these risks is the first step in ensuring a safe working environment.

Proper Training

Ensure that all operators are trained in the safe use of air compressors. This includes understanding equipment controls, safety features, and emergency shut-off procedures. Regular training helps in reinforcing safety practices.

- Conduct safety training sessions for all employees using air compressors.

- Provide written safety manuals and guidelines for reference.

- Organize hands-on training for practical understanding and familiarity with the equipment.

- Update training materials regularly to reflect any changes in safety protocols or equipment specifications.

Regular Inspections

Conduct routine safety inspections to identify any potential hazards, such as leaks or damaged components. Regular maintenance is key to safe operation and can help prevent serious accidents.

- Check pressure relief valves and safety shut-off mechanisms to ensure they function correctly.

- Inspect hoses for wear and tear, replacing any damaged parts immediately.

- Monitor compressor temperature and ensure proper cooling to prevent overheating.

- Keep a maintenance log to track inspection dates and any repairs performed.

Personal Protective Equipment (PPE)

Always use appropriate personal protective equipment when operating air compressors. This may include safety glasses, gloves, and ear protection. PPE plays a crucial role in preventing injuries and ensuring operator safety.

- Ensure operators wear hearing protection in noisy environments.

- Use eye protection to prevent injury from flying debris or air blasts.

- Wear gloves designed for grip and protection when handling tools or attachments.

- Consider wearing respiratory protection when using compressors in confined spaces to avoid inhalation of harmful particles.

Safe Operating Procedures

Establish and follow safe operating procedures to ensure the safe use of air compressors in the workplace. Operators should adhere to these guidelines to minimize risk.

- Always check the compressor’s oil level and change it as recommended by the manufacturer.

- Make sure to drain moisture from the air tank regularly to prevent rust and other damage.

- Use appropriate fittings and hoses that are rated for the compressor's pressure level.

- Avoid exceeding the recommended pressure settings to prevent potential blowouts or equipment failure.

- Never bypass safety features or operate the compressor without the necessary guards in place.

Emergency Procedures

Prepare for emergencies by establishing clear procedures that all operators should know. Having a plan can significantly reduce the risk of injury during unforeseen incidents.

- Post emergency shut-off instructions near the compressor for quick access.

- Conduct regular drills to familiarize all personnel with emergency procedures.

- Provide first aid kits and ensure operators know their locations and how to use the supplies.

- Have contact information for emergency services readily available.

Conclusion

Prioritizing safety when using air compressors is essential. By following best practices, ensuring proper training, and implementing emergency procedures, you can minimize risks and create a safer work environment for all employees. Remember that safety is a collective responsibility, and fostering a culture of safety can significantly enhance workplace conditions.