Screw Compressor Maintenance: Ensuring Reliability and Efficiency

Published on:

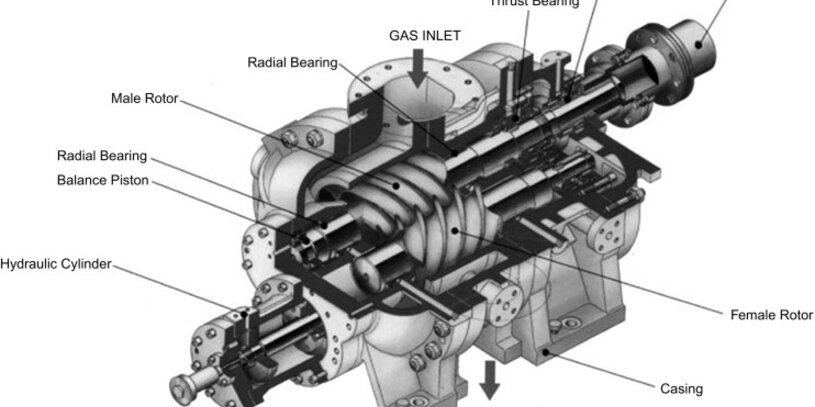

Understanding Screw Compressors

Screw compressors are renowned for their efficiency and reliability, making them a popular choice in industrial applications. They utilize a rotary screw mechanism to compress air, providing a consistent air supply and continuous operation.

Importance of Regular Maintenance for Screw Compressors

Maintaining screw compressors is crucial to ensure they operate at peak efficiency and to prolong their lifespan. Regular servicing can help identify potential issues before they escalate into costly repairs. Key benefits include:

- Continuous Operation: Regular maintenance helps prevent unexpected downtimes, ensuring your operations run smoothly.

- Energy Efficiency: Well-maintained compressors consume less energy, lowering operational costs.

- Longer Lifespan: Routine checks and servicing extend the life of your compressor, maximizing your investment.

Essential Maintenance Tips for Screw Compressors

To keep your screw compressor running efficiently, follow these essential maintenance tips:

- Check Lubrication Levels: Ensure oil levels are adequate and change the oil as recommended by the manufacturer.

- Inspect the Inlet Filter: Clean or replace the inlet filter regularly to maintain airflow quality.

- Clean the Cooling System: Keep the cooling system clean to prevent overheating and ensure optimal performance.

- Conduct Vibration Analysis: Regularly check for unusual vibrations, which may indicate underlying issues.

- Monitor Electrical Components: Regularly inspect electrical connections and wiring to ensure they are secure and functioning properly.

Signs That Your Screw Compressor Needs Servicing

Be alert for the following signs that your screw compressor may need professional attention:

- Increased energy consumption compared to previous performance.

- Unusual noise or vibration during operation.

- Frequent tripping of safety switches.

Choosing the Right Service Provider for Screw Compressors

Select a service provider that specializes in screw compressor maintenance. Look for experienced technicians who can provide comprehensive services, including routine maintenance, repairs, and parts replacement.

Conclusion

Regular maintenance of screw compressors is vital to ensuring reliability and efficiency in your operations. By following these maintenance tips and being aware of the signs of wear, you can significantly enhance the performance and lifespan of your compressor. For expert servicing in the Chakan MIDC, Kurali Mhalunge, and surrounding areas, reach out to Snap Air Compressor for all your screw compressor needs!